Well, what a project!

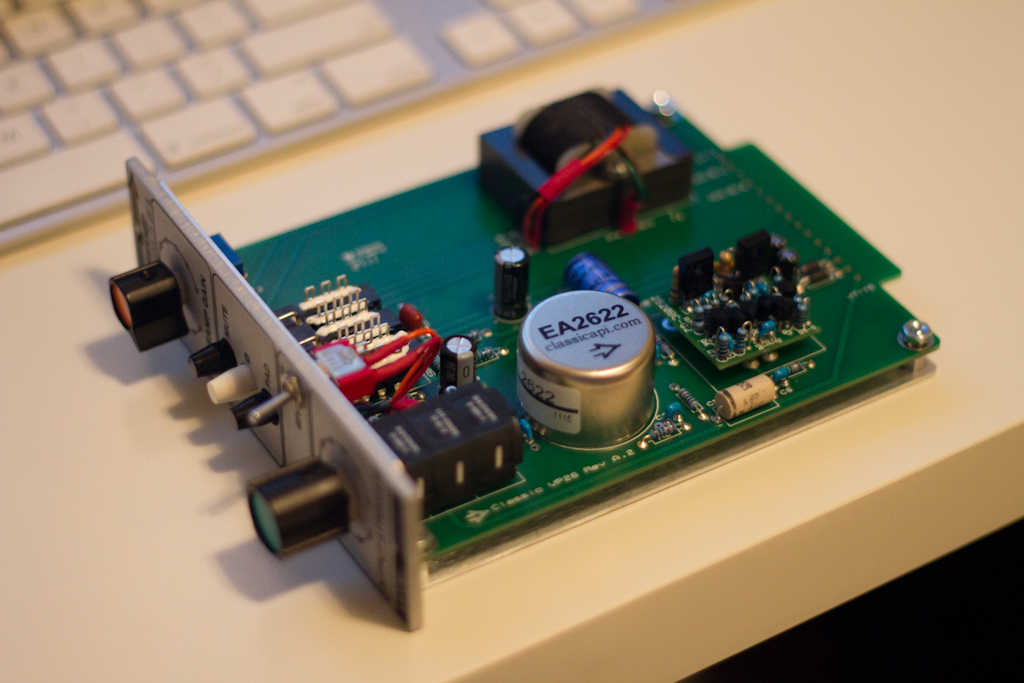

For those who haven’t been following my progress lately, I built ClassicAPI VP26 and Sound Skulptor MP73 microphone pre-amplifiers ( pre-amps ) to use on the album I am currently producing for Lee Safar.

Whilst the pre-amps themselves were fully self-contained kits, the processing of putting them into a 1u rack case, along with some of my own customizations, was a much more time-consuming and complex project than I originally expected.

I am happy to say that as I type this, they are completely working and racked up beautifully in a case I cut with my own hands ( no CNC machines were used this time, just a good old drill press and a bunch of manual labour! ). The next time I undertake such a project, I think that I’ll be relying more on automation, but I wanted to get my hands dirty this time.

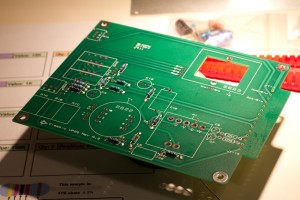

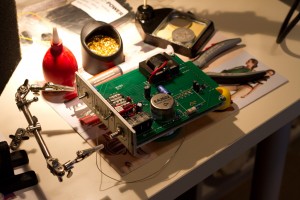

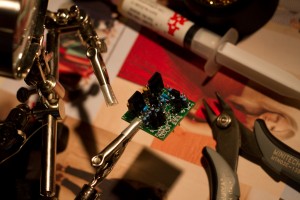

Picking up from my last pre-amp post, I rounded up the last part of the build by assembling everything roughly, and running through the MP73 calibration procedure for a few hours, running a bunch of test tones to and from the unit, and calibrating things like the clipping LEDs etc.

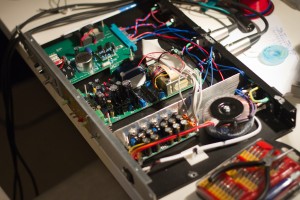

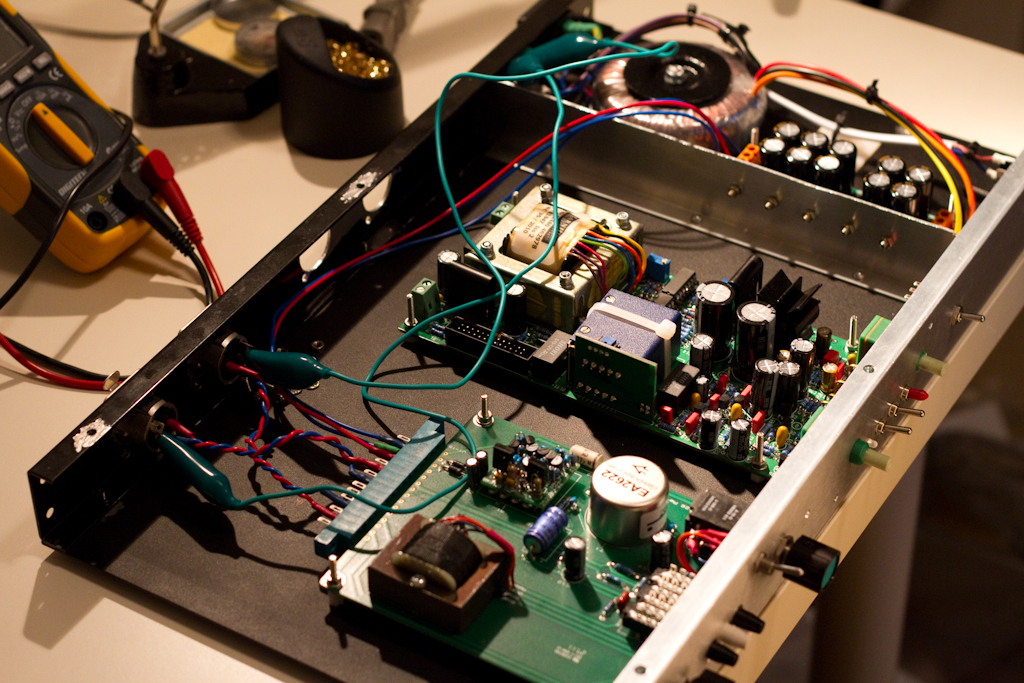

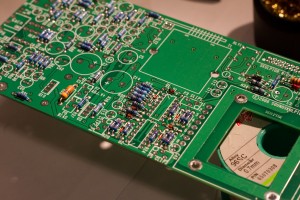

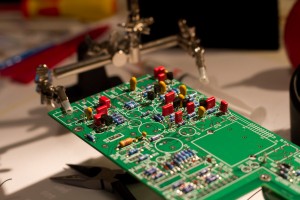

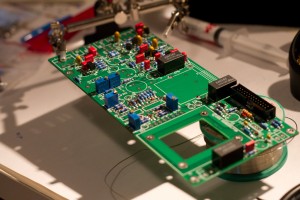

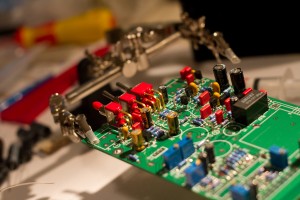

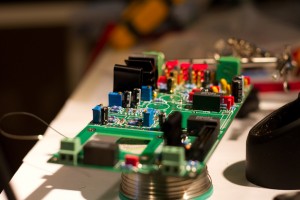

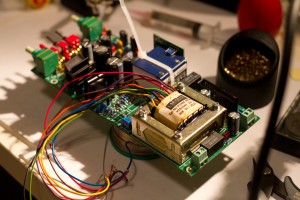

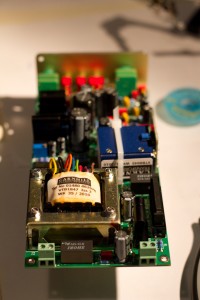

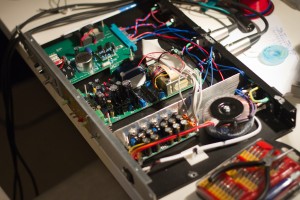

At that point in time, the whole thing looked a little like this:

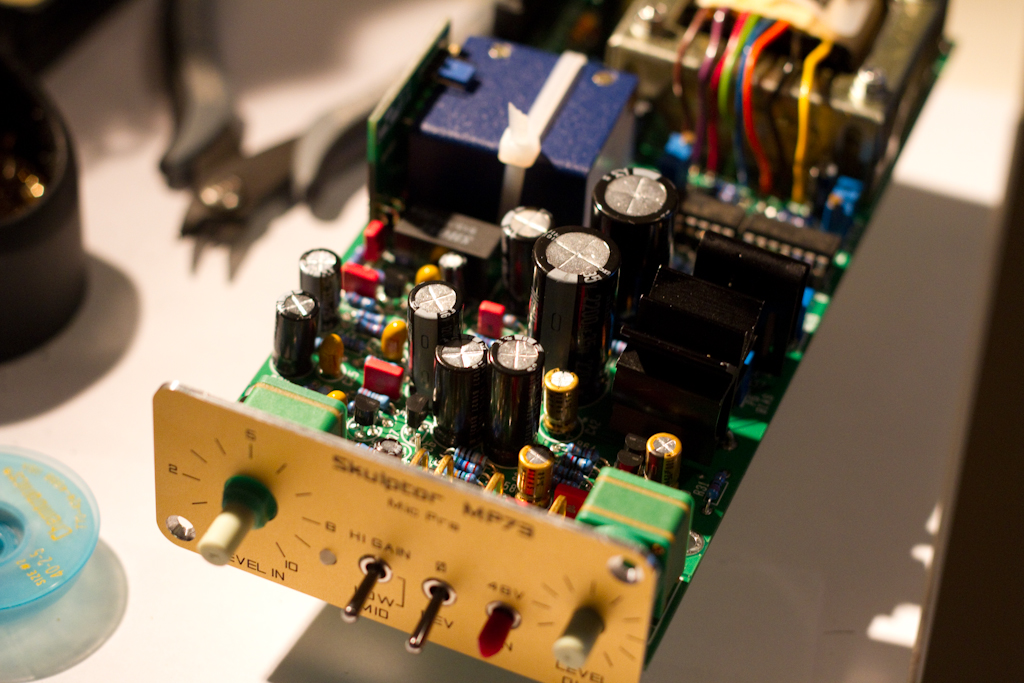

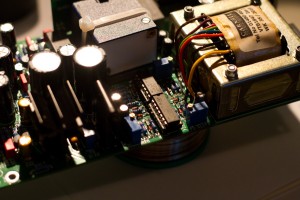

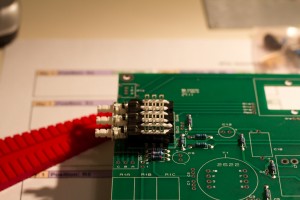

Here you can see the test tones are being fed in to the MP73:

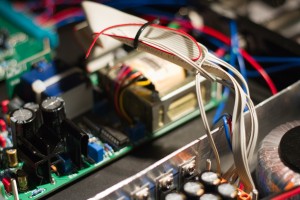

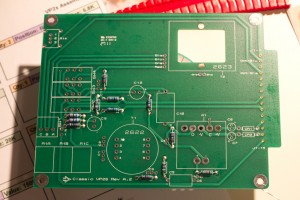

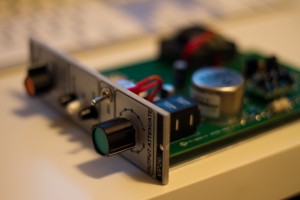

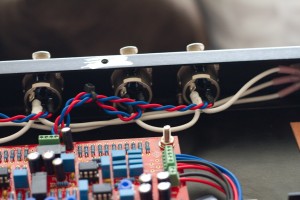

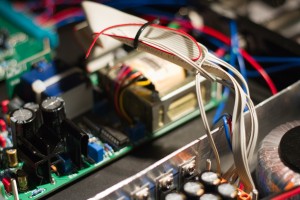

Since the MP73 is designed for a custom Sound Skulptor case, I had to improvise on some of the wiring:

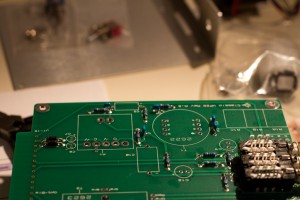

I also had to ensure that the VP26 kept working with the MP73 running simultaneously, since the JLM Audio Powerstation power supply I used was providing all of the various voltages I needed:

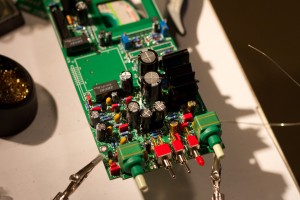

Here was the first image I took of the clip lights on the MP73 operating correctly. That was an exciting time!

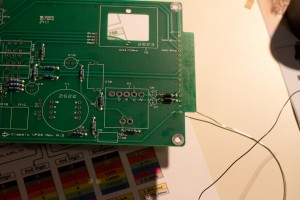

From that point, all that was remaining was the hefty final wiring, which included an extremely cool customization feature that I added for the specific purpose of being able to get a bunch of different tones for the recordings we are going to do of Lee’s vocal.

The Customizations:

Basically, you can see here, an unlabelled little switch just to the right of screen:

When it’s sitting “up”, which is the “off” position – it has no effect. but when you flick it down to the “on” position, it does something pretty cool. It turns on a relay that bridges the two inputs ( if we label the VP26 circuit as pre-amp A, and the Sound Skulptor MP73 as pre-amp B ) so that the inputs for A and B are connected. This means that with the switch down, plugging a single microphone into input A, drives BOTH the preamps A & B, and produces distinct, isolated outputs from both the A & B channels.

This is an intentional cost-cutting feature, designed because we decided not to buy two microphones. Instead, I wired in this bridging mechanism, allowing us to get the phase-accurate sound of BOTH the API and Neve-style pre-amplifiers at the same time, from one source.

This allows us to then record the two different flavors of sound to the Left and Right inputs of a standard sound-card. Cool huh? 😉

The second customization again relates to the bridging swtich, but allows you to still safely use phantom power. With the bridging switch in the “off” position, channels A and B have separately controlled independent phantom power switches. However, with the bridging switch “on”, the phantom power is disconnected from the B channel, and instead, the phantom power from channel A is used only. Since the inputs are bridged, this just means that you get the correct phantom power, controlled by channel A’s phantom power switch, without the hassle of having to worry about the current setting of channel B’s phantom power switch.

It’s basically just a safety feature that allows phantom powered microphones to be used in the bridging confuguration.

I can’t WAIT to use this feature and be able to blend two independent colours of Lee’s voice together to find the right tone.

The Final Images:

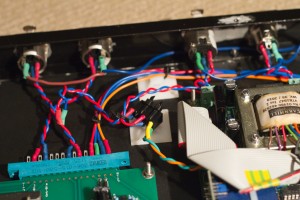

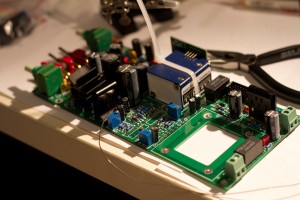

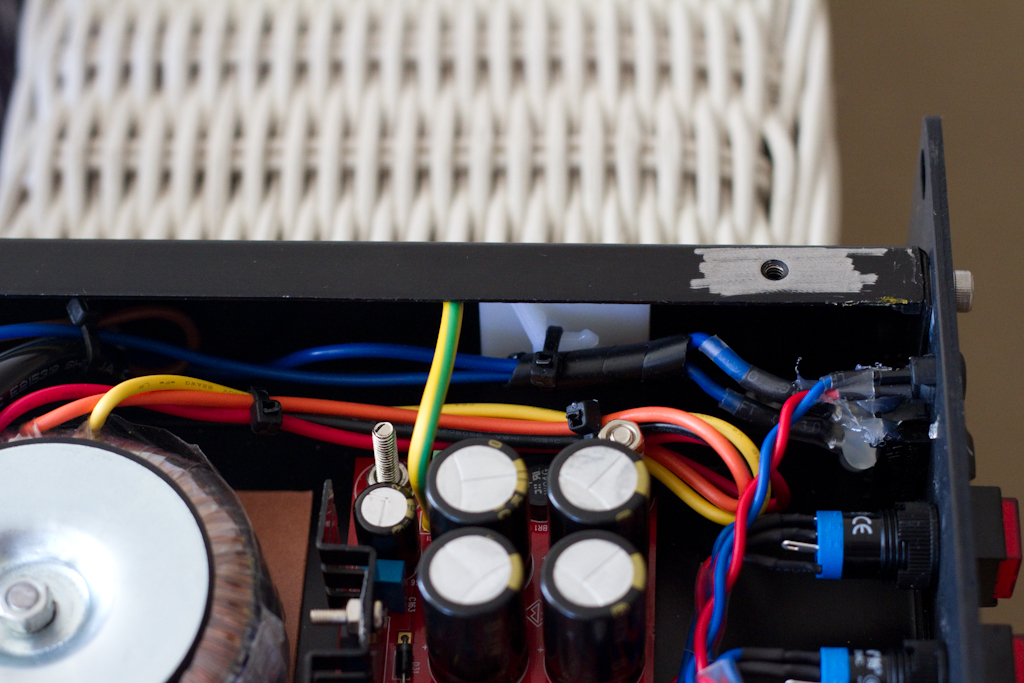

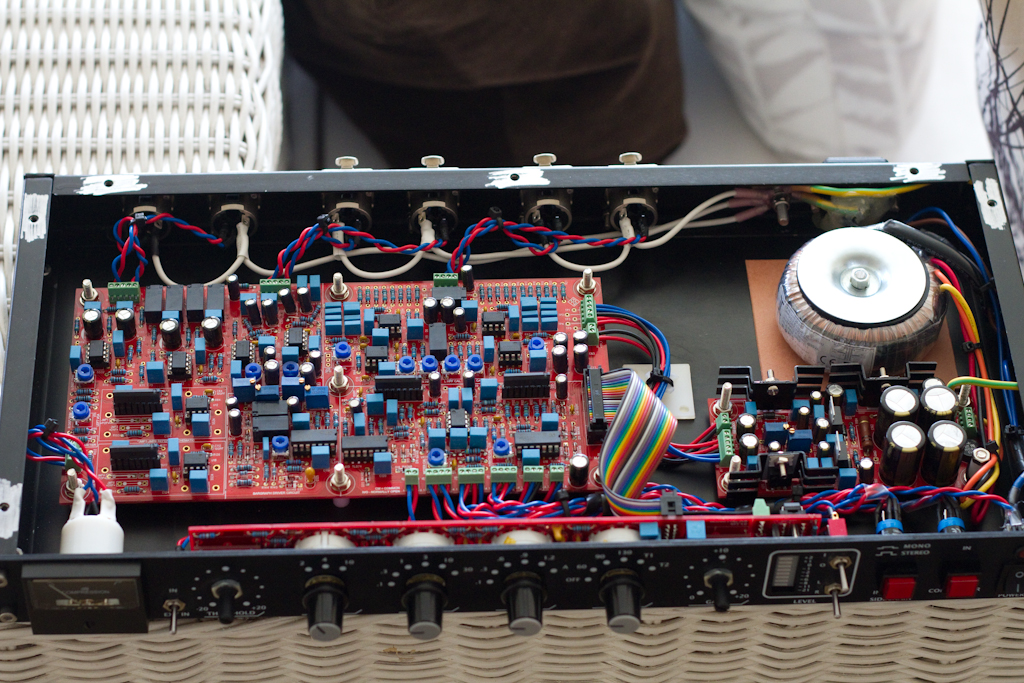

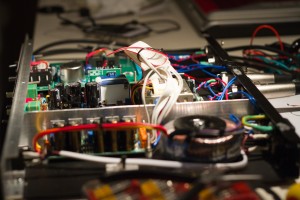

Here it is, completely finished, but with the lid off:

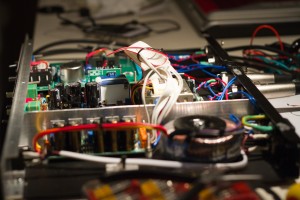

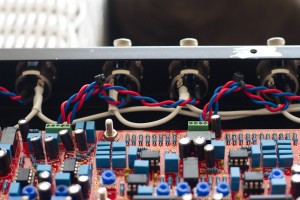

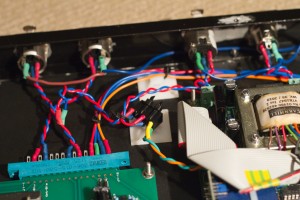

And here are the carefully wired internals:

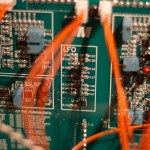

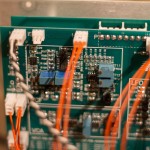

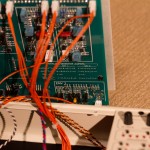

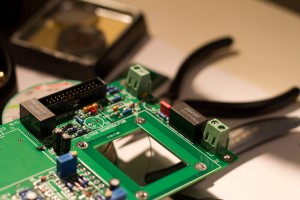

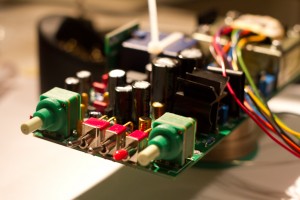

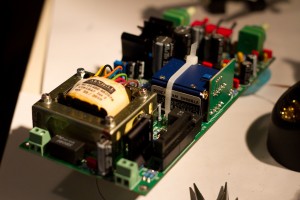

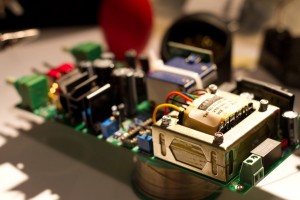

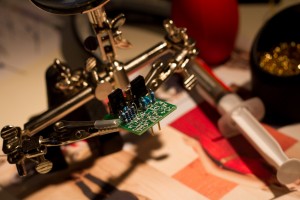

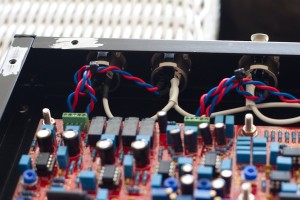

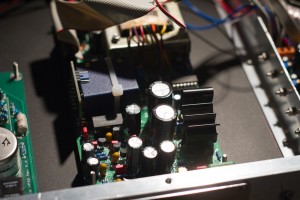

Followed by some close-ups, that show some of the features I’ve discussed:

Here you can see the relay driving the bridging input configuration. It sits right near the inputs to keep the length of cables as small as possible. I didn’t want to run audio cable all the way from the rear inputs, to the front switch, and then back again, so this was a good alternative solution:

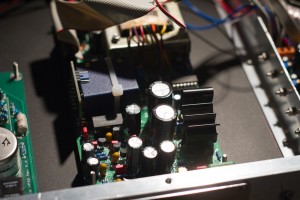

And here are the rest of the internal pics:

Since Lee needs to take this back to LA with her, I’ve included the ability to switch between 120V and 240V input power:

Looking good!

And here it is, trying out a rack space for size, alongside my previous build, an SB4000 SSL-style Bus Compressor ( thanks ruckus! ):

For any details about this, please let me know and I’ll give you whatever information I can.

It was a really fun and challenging project and I can’t wait for Lee to arrive in Australia to start recording the vocals for her album through these.

Sound samples coming soon….