Hi there!

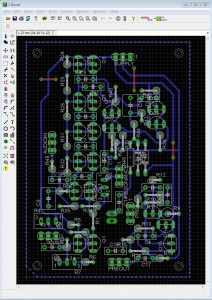

Today was the second day I have spent working on a build of this DIY kit: http://www.prodigy-pro.com/diy/index.php?topic=40971.0.

I obtained a fully inclusive parts kit from this link: http://diypartssupply.com/ which may or may not be stocked when you read this, as their stock levels vary frequently.

I also obtained a PCB and front panel kit from here: http://www.prodigy-pro.com/diy/index.php?topic=40755.0.

I’ll post some photos up from the start of the build yesterday, but I just wanted to share this experience with some words and images, so you can understand how much fun it was and how lucky I am to be in a position to be able to undertake something like this.

So let’s rewind again…. Huh?

OK, so, my name is Luke Emrose and I produce electronic music under the alias “evolutionary theory“. I am a home producer based in Sydney, Australia, with a small studio and I am trying to slowly grow that studio. I have a very detailed plan on precisely how to grow it, and what to grow it with. My goal is, one day, to be writing electronic music soley using analog synthesizers and equipment I have build with my own hands and designs, running software that I’ve designed and programmed myself. I am able to undertake such a giant goal for two mains reasons: the first is that I spent much of my childhood keenly interested in electronics, building everything from some boring flashing lights, to, in high school, designing and building a fully functional 8 channel stereo audio mixing console ( Andrew, do you still have it? 😉 ), and the second is that my full time job is as a Core Software Engineer for a Visual Effects company specializing in Hollywood blockbusters.

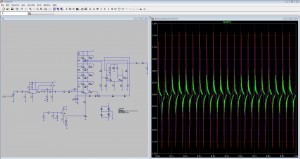

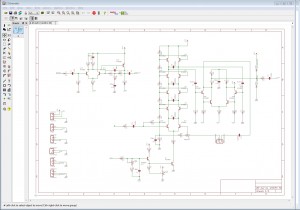

Part of my current set of after-hours tasks is producing an entire album of material for vocalist and general legend Lee Safar. To try and keep costs down, initially we’ll be mixing and mastering the first few album tracks at a professional studio facility, but in the background I am figuring out how to absorb as much of that work back here at my home studio as possible. One piece of equipment that I knew I had to have is the Solid State Logic 4000 G-series Bus Compressor, which inspired the Gyraf DIY GSSL project: http://www.gyraf.dk/gy_pd/ssl/ssl.htm. The SB4000 kit that I’m discussing here was derived from the Gyraf GSSL and contains a number of extremely interesting improvements. It took a long time for me to settle on this particular kit, but it was a combination of cost effectiveness, the quality of the kit, the copious amounts of positive feedback on the Prodigy-Pro forums about the kit, and a bunch of my own research that led me to the decision.

To build the kit I needed some help. It’s been quite some years since I’ve laid eyes a soldering iron, let alone used one…. So, being lucky enough to go to work every day surrounded by some of the most intelligent and resourceful people I’ve ever met, meant that a close friend of mine, Talsit De Cod, could put up his hand and then his house for two days, to turn it into a batcave of circuit building ( his wife was very understanding about the mess we made, thanks for that 😉 xxx )….

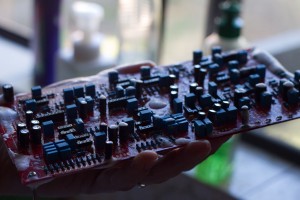

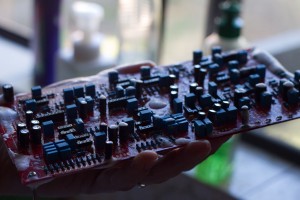

So here we are, on day 2 of the build, each working away soldering at the main SB4000 audio board ( the first image is me, the second is Talsit ):

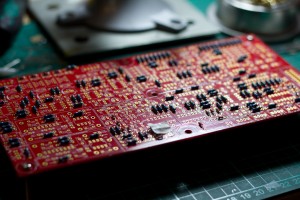

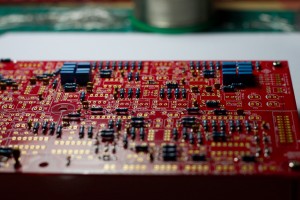

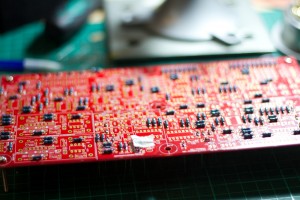

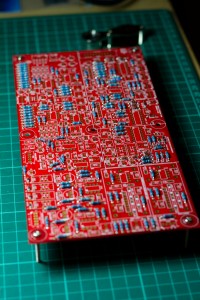

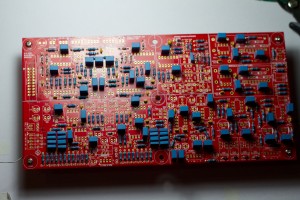

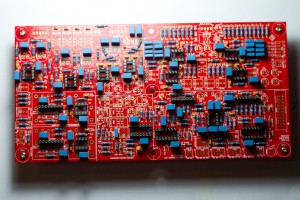

So here is the main audio board populated with resistors and diodes:

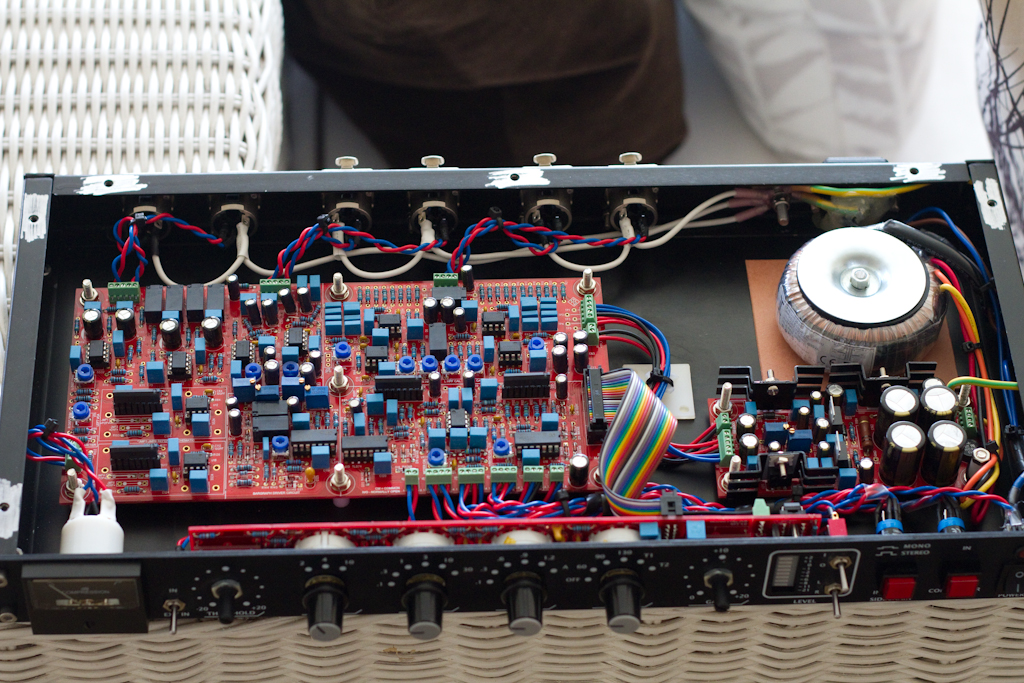

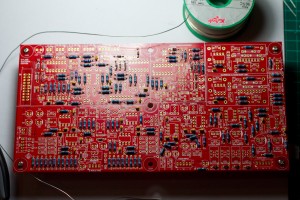

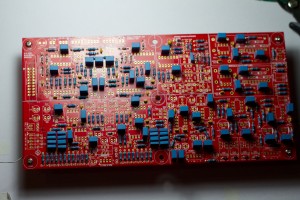

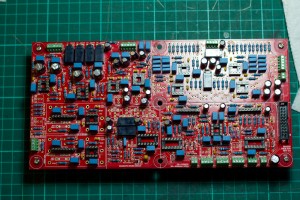

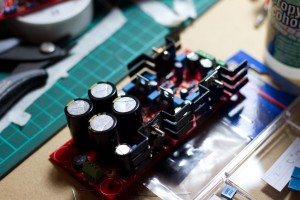

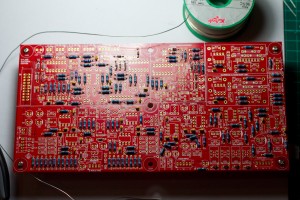

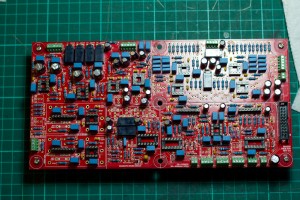

Here is a wide shot showing the mess we made of a table, the main audio board ( left ) plus the control board ( that houses the rotary dials and knobs that the user uses to interact with the compressor ), middle, and the power supply board ( which we built on day 1 ), right:

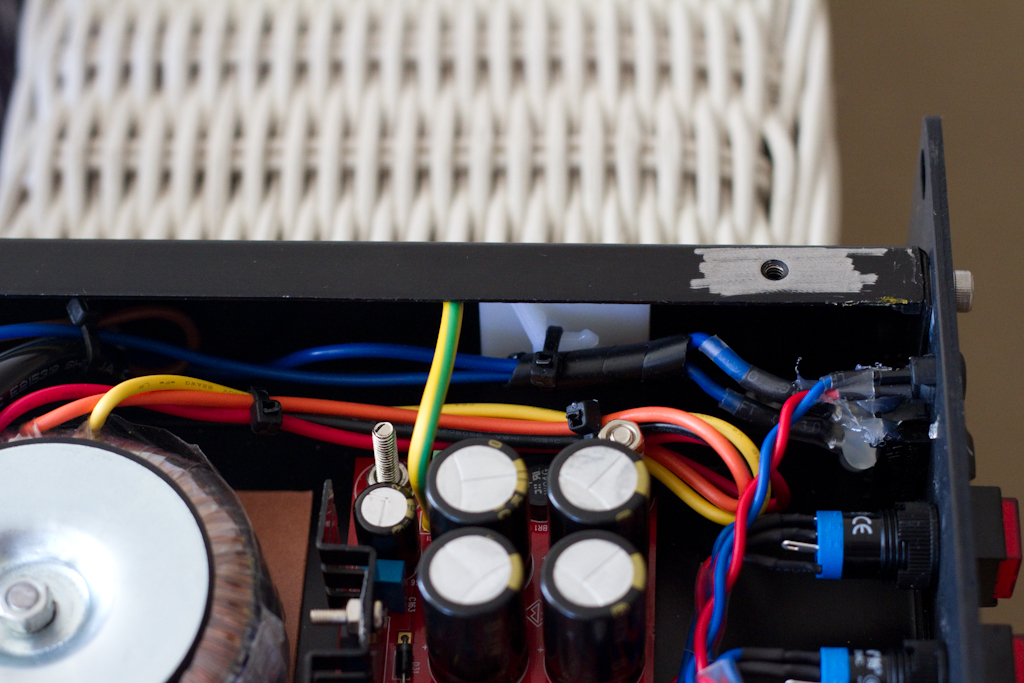

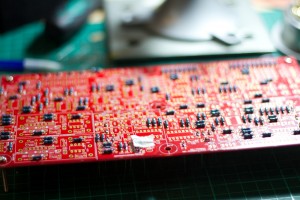

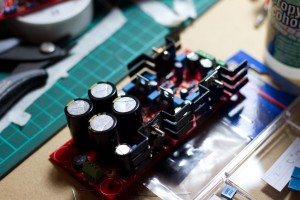

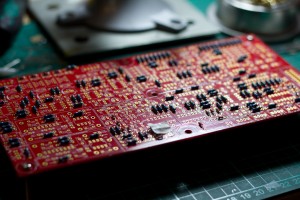

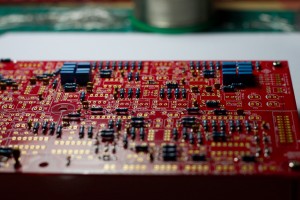

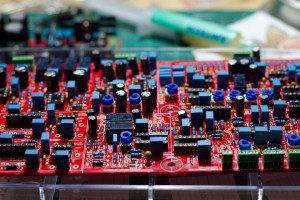

Here are a few more detailed shots of the power supply board ( which I am going to make some changes to by swapping some resistors for trimmers to more precisely control the supply rails to be +-15 and +-12V, currently it’s a little off at about 14.89V and -15.34V and similar for the 12V rails ). I’m a sucker for accuracy ( as is Talsit…. ):

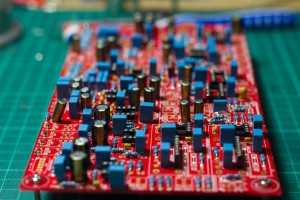

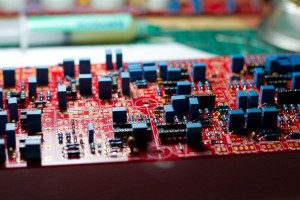

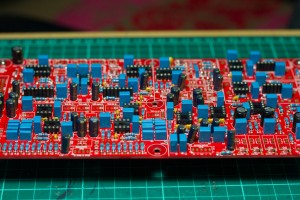

In this picture you can see the SB4000 Revision 4 PCB resistor hack ( the diagonal resistors to the left middle of the frame ). If you decide to build this kit, please remember to read the build manual, which covers this in detail:

If you do not do this, the compressor in bypass mode will invert the phase of the signal.

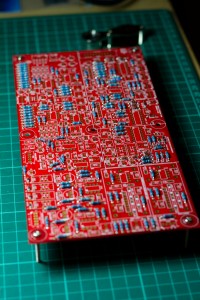

Next we put in the ceramic capacitors ( the orange thingies 😉 ):

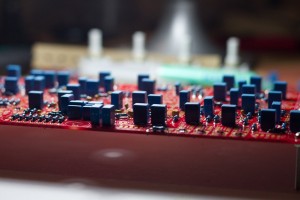

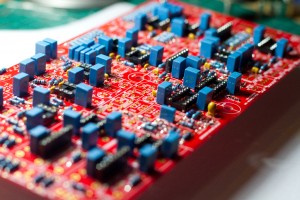

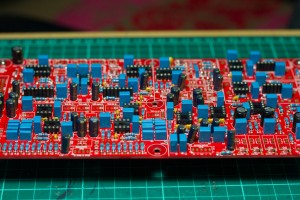

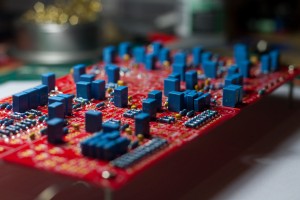

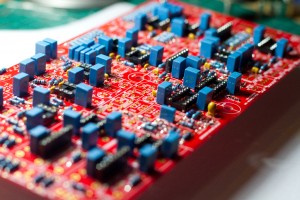

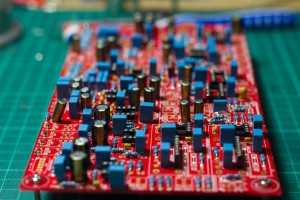

Then some polyester capacitors ( the blue ones ):

Soldering them all in place with great care:

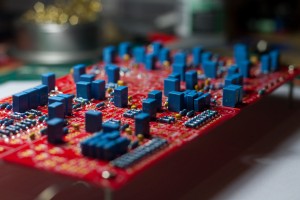

After a LOT of soldering all of the polyester caps were in place, looking like a little city of awesome….

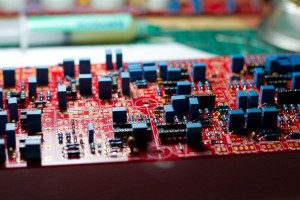

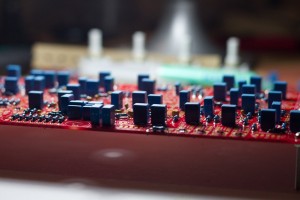

Next we put in the IC sockets ( the black bits ):

Now I know this next part might seem a little weird, but trust me, it IS necessary….

That’s right, we gave the board a wash with soapy water to clean off all of the flux we’d used during the first round of soldering ( flux is a compound that helps the solder stick to the components and board by both cleaning them quickly as a solvent and aiding in the thermal contact between the part and the PCB track and solder to bring them all together. However, it’s very messy, highly corrosive and smells pretty horrid, so you godda get rid of it ):

Please note also that BEFORE washing with water, you need to use a flux remover solution; brushing the solder joints vigorously with a toothbrush ( to dissolve and start to remove the flux ), then use alcohol after that for a further clean, and brush again with a toothbrush or similar ( the alcohol dissolves all bad bits and cleans thoroughly ), and THEN wash in soapy water.

And of course after a good wash, you need a good blow-dry, so:

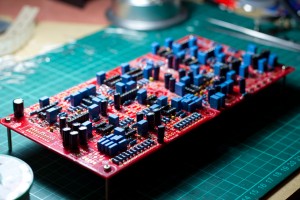

There we go, all nice and clean, ready for mounting the parts that are not sealed ( and hence can’t be washed ):

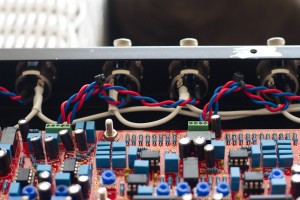

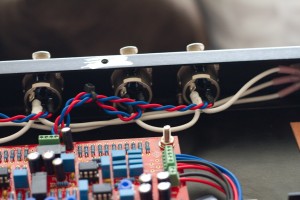

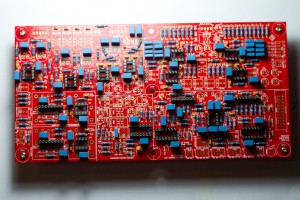

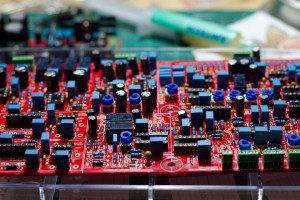

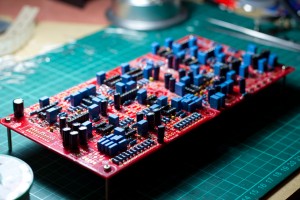

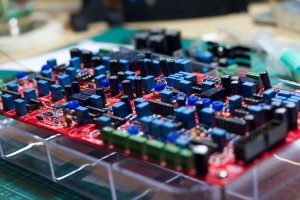

Next the relays ( dark blue ), ribbon cable connector ( black ), and screw terminals ( green ) went in:

Then the trimmers went in ( blue ):

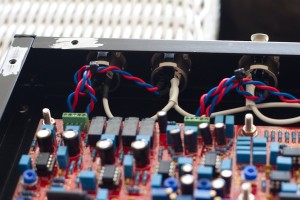

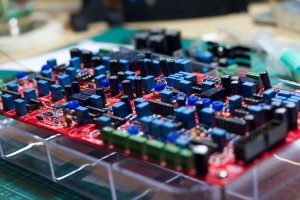

During this whole time, the control board was being finished off too:

There were a few things we needed to solve, like how to mount the bourns potentiometers properly. You get given a daughter board to place them on, but after much fiddling I think we are going to leave the daughter boards off and just mount them straight to the control PCB ( which might create issues with mechanical strength, but we don’t have much choice, since the supplied mounting nuts for the Bourns pots were incorrect and didn’t fit properly ( I’ll post some more images to show this shortly ):

Finally we started to drill the holes to mount the different components that attach to the main case, starting with the toroidal power transformer:

And that’s where we got up to today. Not long to go now hopefully. I feel it appropriate to end with a messy desk, awaiting the last portion of work: